A106 LUTZE DRIVEFLEX® XLPE (C) PVC, Shielded

Flexible VFD Cable XHHW-2 with UL/TC-ER-JP/WTTC/CE Approvals

| Part number | Description No. of conductors incl. ground | OD - Ø ca. mm | OD - Ø ca. inches | Weight Lbs/Mft | Copper Lbs/Mft |

|---|---|---|---|---|---|

| A1061804 | AWG 18 (19/30) AWG18/04C | 10.5 | 0.415 | 108 | 42 |

| A1061604 | AWG 16 (26/30) AWG16/04C | 10.8 | 0.425 | 124 | 54 |

| A1061404 | AWG 14 (41/30) AWG14/04C | 11.6 | 0.456 | 154 | 76 |

| A1061204 | AWG 12 (65/30) AWG12/04C | 13.0 | 0.51 | 208 | 118 |

| A1061004 | AWG 10 (105/30) AWG10/04C | 16.5 | 0.650 | 320 | 183 |

| A1060804 | AWG 8 (168/30) AWG8/04C | 20.6 | 0.81 | 478 | 279 |

| Voltage: | 600V 90C TC-ER-JP 1000V 90C Flexible VFD Servo Cable 1000V 90V WTTC 1000V 105C AWM | |

| Temperature range: | -40°C - +105°C static | |

| Bending radius min: | 6 x cable OD | |

| Conductor marking: | Black with white numbers and one green/yellow ground | |

| Approvals: | UL Type Flexible Motor Supply, Flexible VFD Servo Cable, TC-ER-JP, WTTC, DP-1 Meets NEC 336, 392 Class I,II Div. 2 and Class I Zone 2 per NEC 501, 502, 505 AWM 20886 Submersible Pump (≥ AWG14) c(UL) TC, CIC FT4 UL 1277 RoHS, REACH, TSCA | |

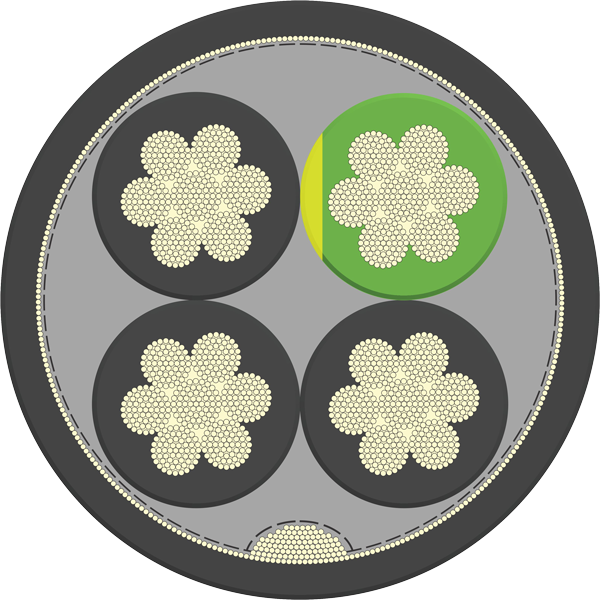

| Construction: | AWG conductor Class K flexible fine wire stranded tinned copper conductors for improved electrical characteristics and reduced oxidation Thermoset XLPE insulation type XHHW-2, Wet/Dry Shielded with foil tape, tinned copper braid with ≥80% optical coverage, and drain wire Oil resistant PVC jacket Black jacket similar to RAL 9005 | |

| Oil resistance: | Oil Res II Specifications subject to change without prior notice |

| Capacitance | Impedance | |||

|---|---|---|---|---|

| Part number | Mutual (pF/ft) | Ground (pF/ft) | Mutual (Ohms) | Ground (Ohms) |

| A1061804 | 21.9 | 38.4 | 90.2 | 52.5 |

| A1061604 | 23.8 | 43.3 | 81.6 | 54.2 |

| A1061404 | 25.7 | 42.7 | 69.1 | 38.6 |

| A1061204 | 29 | 52.5 | 48.6 | 26.9 |

| A1061004 | 29.2 | 48.32 | 40.9 | 24.15 |

| A1060804 | 26.2 | 45 | 52.4 | 33.3 |